Gate loop detectors are a purposeful work of art. Through them, vehicles can pass through gates unobstructed without manually operating them. In the past, these were used to trigger traffic lights. But today, gate loop detector installation is becoming integral in many gateways.

What Are Gate Loop Detectors?

The gate loop detector is made of insulated and inductive loop wires. The wires are typically installed in a square or rectangular pattern and run continuously without splices. The detector is installed underground within or near the traffic barrier, gate, or access control system.

One end of the wire is attached to the loop detector or terminal of the gate operator, which transmits the energy into it.

The detector creates a magnetic field along the wire and enables it to resonate at a certain frequency. When the wire senses metals such as vehicles, it relays information to the operator to open. It will remain open until the vehicle passes before it relays a close signal again.

Driveway safety loop detectors have a similar mechanism to a door or gate safety sensor. The difference is that gate safety loops are limited to metal objects and will not detect pedestrians and animals.

There are also wireless safety loops that detect metal through magnetism. These are attached to the ground surface and communicate wirelessly with the transceiver of the gate controller. A wireless safety loop is a convenient vehicle loop detector, reducing the need for digging and wiring to install the induction loop.

Different Types/Applications of Gate Loops

Loop detectors are not only designed for entry points. They also come in different types for a particular application that you need. The most common are:

- Free Entry Loop. This is the most popular and is used to open an automatic gate or lift a barrier arm operator.

- Exit Loop. It triggers the gate to open for leaving vehicles.

- Reversing Loop or Interrupt Loop. This stops the direction of an automatic gate or barrier arm. It will remain open until the vehicle has passed.

- Shadow Loop. It is used in a swing gate, which is installed inside the gate. Its function is to make sure that the swing gate closes when the vehicle is already out of the way.

- Close Loop. This is used in barrier arms that automatically lower it when the vehicle clears the loop.

- Arming Loop. This one is used to control and access a site, so the vehicle must drive into the loop to use an access device like a card, intercom system or telephone entry system.

Can I DIY a Gate Loop Detector Installation?

It can be tricky, but yes, you can DIY a gate loop detector installation as long as you know what you are doing.

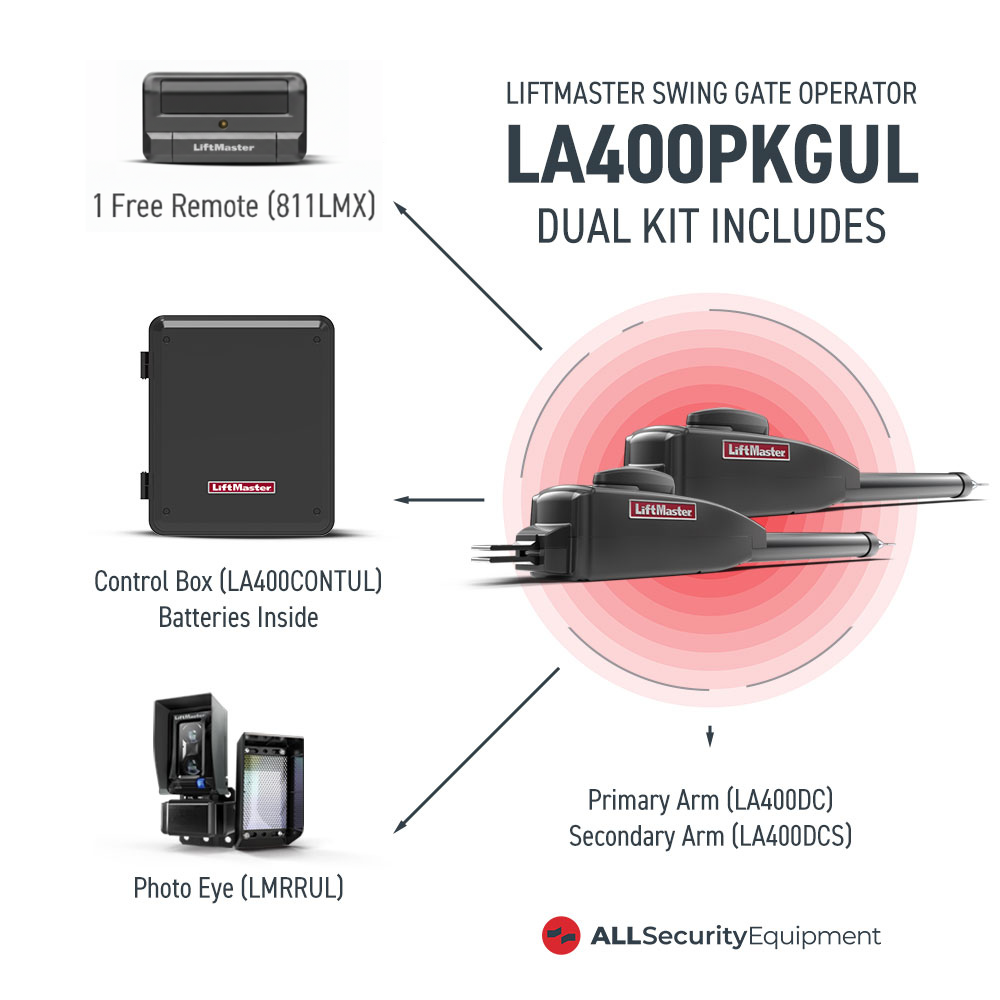

The first thing you need to do is buy a reliable gate loop detector terminal. You can find a few good quality brands like LiftMaster, All-O-Matic, EMX, Linear and Diablo. A reliable detector is necessary for the ground safety loop to also work reliably for vehicle access.

You also need a loop and feeder wire, such as BD Loops. The wire must be continuous, which means it does not have any breaks or splices. It is ideally made of cross-linked polyethylene (XLPE) or polyester insulation. Loop wire comes in 14, 16 or 18-gauge sizes.

To Install a Gate Loop Detector

- Mark the pavement with a layout and saw-cut a groove on the pattern. The typical depth of the ground loop is 2 to 2.5 inches to ensure about an inch of clearance from the top of the wire to the pavement. The groove must be larger than the diameter of the loop wire.

- Make a V-cut for the yoke or the area where the loop meets with the lead-in wire.

- Remove all the debris from the cut to make sure that the bottom is smooth. An air compressor does the job well.

- Insert the loop into the groove according to your user manual. If using a BD loop, install the loop with the black wire side up and red side down.

- Do not push the wire fully in yet so you can adjust its position while aligning.

- Align the yoke into the V-cut.

- Push the loop down into the groove.

- Twist the wire with a minimum of 6 turns per foot from the end of the feeder to the terminal. It helps reduce interference and noise.

- Apply a loop sealant to the lead-in wire in the V-cut and push it down completely.

- Apply more loop sealant into the groove following the package instructions. Let dry and clean the surface thoroughly.

Wiring the Gate Loop Detector

- Plug the loop detector into the compatible gate opener. Refer to the user manual provided by the manufacturer. For LiftMaster gate operators, the expansion board of the operator is labeled Shadow, Interrupt or Exit for the application that you need.

- Configure the frequency by adjusting the DIP switches or Program dial of the detector. It varies according to brands. The frequency setting is used in multiple loop installations and is used to prevent interference of these loops.

- Adjust the sensitivity setting on the dial. It is used for adjusting the detection level at different thresholds. The typical setting is at 3 to 4. The lowest sensitivity is best for detecting large vehicles, while the highest sensitivity is for smaller ones.

- Test the sensitivity of the loop by driving a vehicle and adjust the sensitivity when necessary. You can push the RESET button if you want to recalibrate the loop.

More Tips on Gate Loop Detector Installation

For gate safety loops to work reliably, the most important thing is choosing your hardware wisely. Feeder wires must be made of durable material that is weatherproof and heat-resistant. The wires should also have excellent conductivity.

The loop should be installed in a square or rectangular shape with a minimum of 1 meter distance between the opposite sides.

The size of the loop depends on the driveway size and typical cars that utilize it. At the most basic and conservative estimate, the short side of the loop can detect about 2/3 of its length. It is ideal for small driveways and cars.

If you have more questions about loop size, loop detectors and gate ground safety loop detector installation, contact us at All Security Equipment. Our team of experts will assist you with everything you need for convenient and safe driveway operations.