In the field of manufacturing automation, efficiency and safety are two paramount factors that cannot be overlooked. One critical device that is used to facilitate these two factors is a photo eye sensor, also known as a photoelectric sensor.

A photo eye sensor is a device that uses light beams to detect the presence, absence, or movement of objects and then sends an on-and-off signal to the input of a programmable logic controller (PLC) to enable various manufacturing automation.

While these devices seem simple, their seemingly simple basic functions can be translated into a multitude of benefits for various industrial applications.

In this article, we describe the three main types of photo eye sensors available on the market and the benefits that they offer when used in industrial settings.

Types of Photo Eye Sensors

There are three main types of photo eye sensors used in industrial and commercial settings:

Through-Beam Photo Eye Sensor

Through-beam photo eye sensors work by emitting a light beam from a transmitter, which needs to be received by a receiver unit on the opposite side. When an object interrupts the beam, the sensor detects it.

Retroreflective Photo Eye Sensor

In retroreflective photo sensors, both the transmitter and receiver are housed in the same unit. The light beam is typically directed towards a reflector placed on the opposite side of the sensor. When an object interrupts the beam bouncing back from the reflector, detection occurs.

Diffuse Photo Eye Sensor

In diffuse photo eye sensors, the transmitter and receiver are contained in the same housing, and the light beam is emitted towards the object and then reflected off the object itself. This reflected beam returns to the receiver for detection.

The Benefits of Photo Eye Sensors in Industrial Settings

The advantages offered by photo eye sensors extend beyond simply detecting objects.

Below are some of the advantages they offer in industrial settings for industrial automation:

Enhanced Automation

The facilitation of automation is perhaps the most important benefit of using photo eye sensors in an industrial setting. Photo eye sensors can automate various tasks, therefore eliminating the need for manual intervention.

A good example is triggering conveyor belts to start or stop based on the presence of materials, helping you streamline your production line and save energy required for production.

Improved Material Handling

Since photo eye sensors can accurately detect the presence and potion of objects in real-time, depending on the sensitivity, this feature allows robots or other automated equipment to precisely pick and place materials during assembly or packing processes.

Inventory Management

Photo eyes can be integrated with inventory control systems to track the movement of goods within a facility like warehouses and production facilities. This application ensures accurate stock levels and prevents shortages.

Enhanced Access Control

Access control is an important part of the security and safety of any manufacturing or commercial facility, and the ability to integrate logical sensors like the Linear Photo Eye With Reflector and Hood from Linear is great for enhancing access control.

By using photo eye sensors in conjunction with automatic door openers, they can ensure that the appropriate doors only open when authorized objects like forklifts carrying materials for dispersal are present. This application can help to optimize traffic flow and prevent unauthorized entry.

Improved Safety

Photo eye sensors are used extensively to ensure industrial safety in a lot of industrial applications. They can be used to detect people entering hazardous zones and, when connected to appropriate access control systems, can trigger alarms or machine shutdowns to prevent accidents.

Reduced Downtime

By using photo sensors to automate your facility’s processes, you can ensure smooth material flow, which, in turn, helps to minimize production downtime and enhance the overall efficiency of your manufacturing process.

Versatility Across Applications

Last but not least, photo eye sensors can do everything from simple counting tasks to complex sorting applications, making them useful in a wide range of applications in industrial settings. Whether you need to detect missing parts in a production line or trigger automatic packaging machinery, you can count on the adaptability of photo eye sensors.

Using a Photo Eye Sensor in Industrial Settings

Photo eye sensors definitely play a crucial role in modern industrial settings, and their ability to accurately detect objects, coupled with increasing sophistication in features and functionality, makes them a valuable tool in enhancing the efficiency, safety, and automation of manufacturing processing. As technology continues to evolve, we can continue to expect more advanced sensor capabilities to emerge, further revolutionizing the way industries operate.

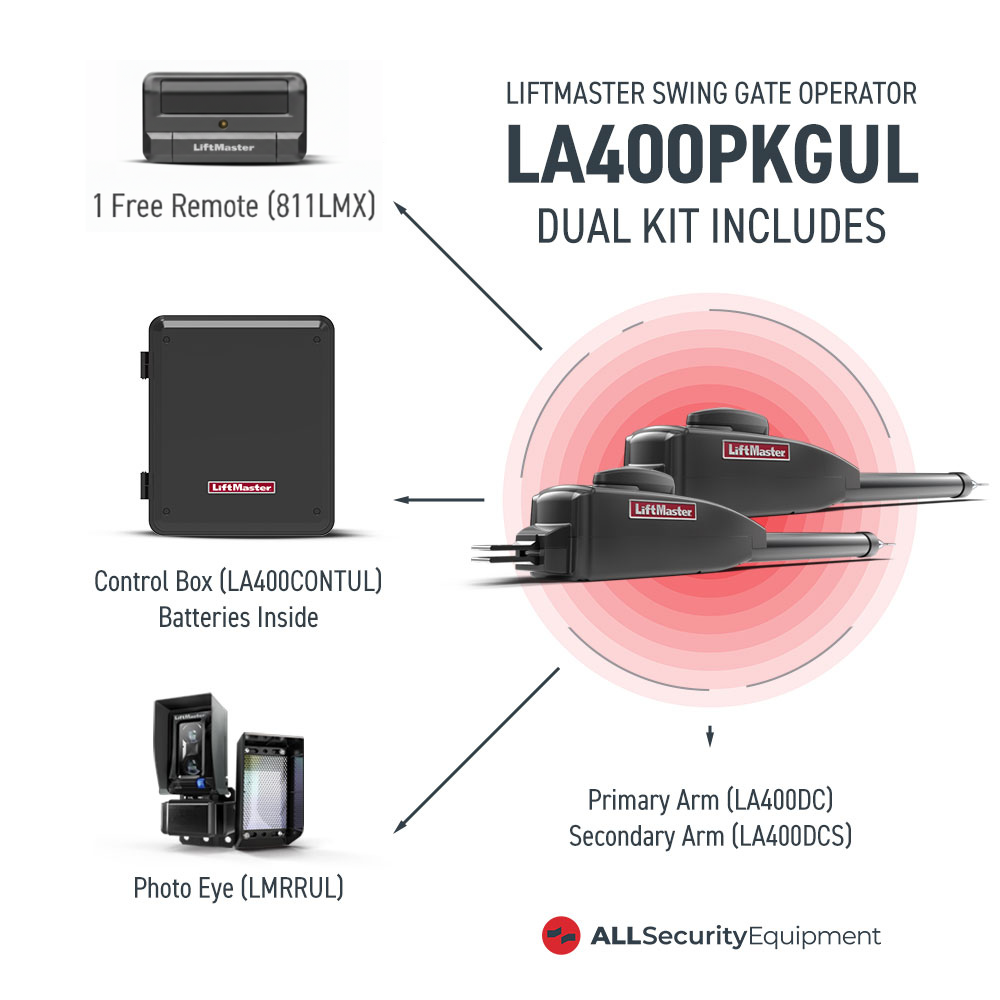

Our Collection of Photo Eyes and Photo Sensors includes Sensors from renowned brands like LiftMaster, BFT, FAAC, and Viking Access Systems.

Regardless of the brand you decide on, our team of industrial application experts is always available to help you install, maintain, and check Industrial setup to ensure efficient Photo Eye Sensor operations.

Contact us to learn more about our products and services.