Low voltage wiring is typically any type of electrical wiring that carries 50 volts or less, and this type of wiring forms the backbone of most modern security and communication systems.

While low voltage wiring might sound less dangerous than high voltage applications and wiring, it still requires knowledge and proper technique to ensure your safety and optimal system functionality.

Some common low voltage wiring components include SCP HDMI cables with Ethernet, coaxial cables, fire alarm cables, shielded audio cables, lightning control cables, and Access control composite cables.

This article explores the four common mistakes that you should avoid when working with low voltage wiring.

1. Ignoring Safety Precautions

When working with high voltage or low voltage wiring, your priority must be your safety and the safety of those around you. Yes, we know that low voltage wiring poses minimal risk of serious shock compared to high voltage wiring applications.

However, complacency with low voltage cable wiring can still lead to injuries and damage.

Here are some safety practices to keep in mind:

- Turn Off Power: You should never start working on any low voltage wiring system without turning off the system first. You can do this by turning off the power at the breaker or transformer. You can double-check that the system is powered down by using a voltage tester before proceeding.

- Use the Appropriate Tools and Equipment: Insulated tools and equipment that are designed to work with low voltage systems are a must-have when you need to work on low voltage wiring. Some of these tools include wire strippers, voltage testers, screwdrivers, pliers, wire cutters, and gloves. Never use damaged tools to work on electrical wire systems.

- Personal Protective Equipment (PPE) is Important: Personal protective equipment is not always necessary for low voltage projects, but the area you need to work in might require that you have full or partial PPE on. These areas are typically sections around manufacturing plants and mining stations.

- Always Work in a Dry Environment: Moisture increases the risk of electrical short-circuiting and electrocution, which is why you should ensure that the area you want to work in is dry. Avoid working on rainy days or in areas where the humidity is high.

2. Not Understanding the Wire Gauge

Low voltage wiring typically comes in various gauges and with stipulated current-carrying capacities.

Your system can develop faults if you use the wrong gauge.

Two common problems you can encounter by using the wrong gauges include:

- Overloaded Circuit: Wire gauges that are too small for the system’s stipulated working current will potentially overheat and melt, causing damage to surrounding wires and posing a fire hazard for your team.

- Voltage Drop: Thin gauge wires generally have higher resistance, which may lead to voltage drops over longer distances. Therefore, ensure you use the right gauge of wire for the recommended distance. If not, you might have a system in which inadequate power reaches the connected devices, which may cause malfunctions or power system performance.

Understanding Wire Gauge

Below are tips for understanding wire gauges and the properties they offer:

- Lower gauge numbers indicate that you have a thicker wire with a higher current capacity. For example, an 18 gauge wire is thinner than a 14 gauge wire.

- Low voltage systems use wires between 18 gauge and 12 gauge, depending on how much power the system needs.

- We recommend that you always consult your system’s manual or manufacturer’s specifications as a reference for choosing the appropriate wire gauge for your intended application.

3. Improper Wiring Practices

There are specific practices that we recommend that you adopt when working with low voltage wiring to ensure that you have reliable connections throughout your system and effective system functionality.

Below are some of the common mistakes you should avoid:

- Over-stripping wires: Baring too much conductor when stripping your low voltage wires can lead to shorts within your circuit, which consequently leads to circuitry malfunctions. Strip only the amount of insulation needed to properly connect the low voltage wire to the intended system.

- Loose Connections: If your wires are poorly terminated, then you might get a system with too much resistance or one in which the leading voltage drops and causes potential connection failures. Make sure every connection you implement is secure and snug. Use tools like crimping tools and screw terminals to ensure secure connections.

- Mixing Wire Types: One common mistake among engineers is mixing solid core and stranded core low voltage wires within the same terminal. While stranded wires offer more flexibility, they require proper termination techniques for a secure connection to take place.

- Incorrect Polarity: Some low voltage systems, like those found in smart homes and other low voltage cabling, are polarity-sensitive, and this means the positive and negative ends of the wires need to be connected correctly.

Make sure you double-check the polarity requirements of the system that you are working on and ensure proper connections to prevent malfunctions or system shorting.

4. Neglecting Labeling and Documentation

Since you never know who will work on the system that you are currently working on in the future or when you will work on the system next, it is highly recommended that you label your low voltage wire.

This will save you numerous headaches when troubleshooting or making system modifications in the future.

- Labeling Wires: label each wire clearly at both ends by indicating its function and destination device or end-point. You can use heat shrink labels or permanent markers for clear and long-lasting classification.

- System Documentation: We highly recommend that when performing low voltage wiring, you create a basic system diagram or document that outlines the wiring layouts, connection points, and device locations. This will serve as a reliable reference material for future modifications and troubleshooting.

Additional Tips for Low Voltage Wiring

Below are additional tips that may help with your low voltage wiring:

- Maintain Slack Wires: You never know what kind of modification your current low voltage system might need in the future. This is why we recommend that you leave some slack wiring during low voltage wiring installation, which allows for easier manipulation during maintenance or future mods.

- Avoid Sharp Bends: Avoid placing your wires around sharp bends, as this can cause the insulated parts to suffer damage and affect the conductors, which may cause system failure.

- Protect the Low Voltage Wires From Damage: You should ensure that your wires are routed away from areas of high-damage potential, such as high-traffic areas, sharp edges, or heat and moisture sources. We recommend that you consider using conduit or cable protectors in appropriate areas.

- Seek Professional Help for Complex Systems: if your low voltage wiring system is for intricate security or communication systems, we advise that you seek the help of a qualified low voltage installer. Their experience and expertise would ensure that you have a safe and functional system.

Get High-Quality Wires and Equipment for Low Voltage Wiring

Low voltage wiring systems are sensitive pieces of technology that require high-quality electrical wiring that can send even the smallest signals and voltages over large distances with little to no drop in signal quality.

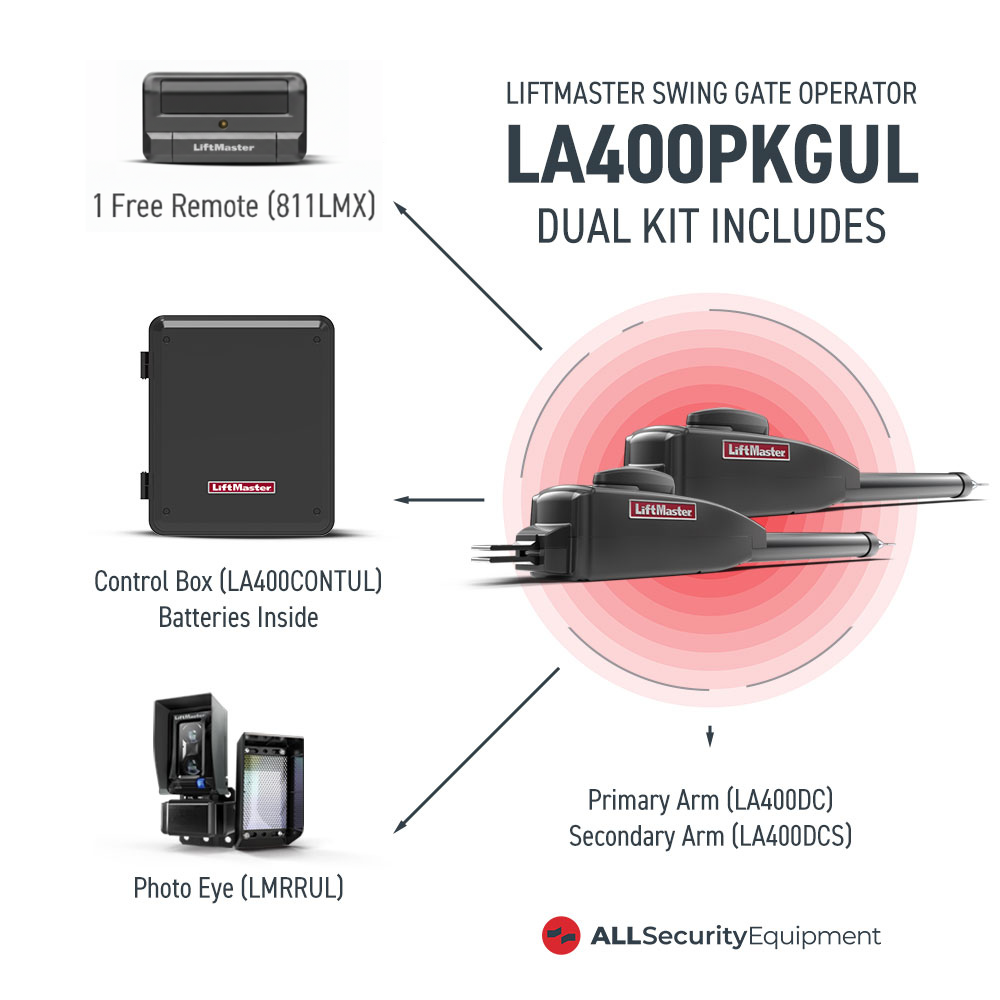

All Security Equipment is a prime supplier of low voltage wiring tools and accessories from top manufacturers globally.

One of our major partners in the low voltage wiring sector is Structured Cable Products, a global manufacturer of cabling products designed for various installations, including data transmission, telecommunications, and security.

We don’t just supply low voltage system equipment and accessories. We also provide high-quality tools to ensure that you and your team remain safe while working on low voltage wiring projects.

Visit our website to learn more about our products and services. If you prefer to talk to a representative, you can speak with our customer service agents instead.